LOCKING ELEMENTS - SWLE 100 TYPE

|

|

|

|

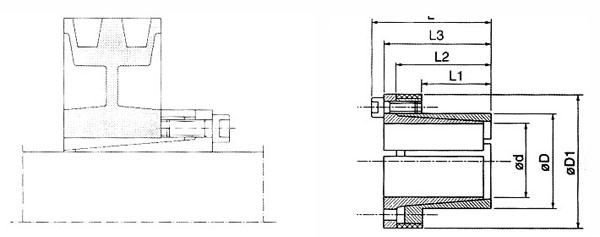

Dimensions (mm)

| SWLE

100 d x D |

L1 |

L2 |

L3 |

L |

D1 |

Torque |

Axial Thrust Fass. |

Surface

Pressure on |

Tightening

screws |

Weight (g) |

||

| Shaft

Pw |

Hub

Pn |

DIN

912 12.9 |

Tightening

torque Ms |

|||||||||

| Nm |

KN |

N/mm2 |

N/mm2 |

No

x type |

Nm |

g |

||||||

| 12

x 18 |

14 |

23 |

26 |

30 |

32 |

58 |

10 |

160 |

105 |

4

X M4 |

5 |

80 |

| 13

x 23 |

14 |

23 |

26 |

30 |

38 |

63 |

10 |

140 |

80 |

4

X M4 |

5 |

125 |

| 14

x 23 |

14 |

23 |

26 |

30 |

38 |

68 |

10 |

130 |

80 |

4

X M4 |

5 |

120 |

| 15

x 24 |

16 |

29 |

36 |

42 |

45 |

127 |

17 |

185 |

115 |

3

X M6 |

17 |

257 |

| 16

x 24 |

16 |

29 |

36 |

42 |

45 |

136 |

17 |

175 |

115 |

3

X M6 |

17 |

250 |

| 17

x 26 |

18 |

31 |

38 |

44 |

47 |

180 |

22 |

190 |

125 |

4

X M6 |

17 |

280 |

| 18

x 26 |

18 |

31 |

38 |

44 |

47 |

200 |

22 |

180 |

125 |

4

X M6 |

17 |

270 |

| 19

x 27 |

18 |

31 |

38 |

44 |

49 |

210 |

22 |

170 |

120 |

4

X M6 |

17 |

290 |

| 20

x 28 |

18 |

31 |

38 |

44 |

50 |

220 |

22 |

160 |

115 |

4

X M6 |

17 |

300 |

| 22

x 32 |

25 |

38 |

45 |

51 |

54 |

250 |

22 |

115 |

80 |

4

X M6 |

17 |

385 |

| 24

x 34 |

25 |

38 |

45 |

51 |

56 |

270 |

22 |

105 |

75 |

4

X M6 |

17 |

405 |

| 25

x 34 |

25 |

38 |

45 |

51 |

56 |

280 |

22 |

100 |

75 |

4

X M6 |

17 |

390 |

| 28

x 39 |

25 |

38 |

45 |

51 |

61 |

465 |

33 |

135 |

97 |

6

X M6 |

17 |

475 |

| 30

x 41 |

25 |

38 |

45 |

51 |

62 |

510 |

33 |

127 |

90 |

6

X M6 |

17 |

480 |

| 32

x 43 |

25 |

38 |

45 |

51 |

65 |

540 |

33 |

120 |

90 |

6

X M6 |

17 |

520 |

| 35

x 47 |

32 |

45 |

52 |

58 |

69 |

790 |

45 |

105 |

80 |

8

X M6 |

17 |

630 |

| 38

x 50 |

32 |

45 |

52 |

58 |

72 |

860 |

45 |

100 |

75 |

8

X M6 |

17 |

670 |

| 40

x 53 |

32 |

45 |

52 |

58 |

75 |

900 |

45 |

95 |

70 |

8

X M6 |

17 |

735 |

| 42

x 55 |

32 |

45 |

52 |

58 |

78 |

950 |

45 |

90 |

70 |

8

X M6 |

17 |

780 |

| 45

x 59 |

45 |

62 |

70 |

78 |

86 |

1890 |

84 |

100 |

85 |

8

X M8 |

41 |

1,230 |

| 48

x 62 |

45 |

62 |

70 |

78 |

87 |

2010 |

84 |

105 |

80 |

8 X M8 |

41 |

1,240 |

| 50

x 65 |

45 |

62 |

70 |

78 |

92 |

2100 |

84 |

100 |

75 |

8

X M8 |

41 |

1,400 |

| 55

x 71 |

55 |

72 |

80 |

88 |

98 |

2600 |

94 |

85 |

65 |

9

X M8 |

41 |

1,700 |

| 60

x 77 |

55 |

72 |

80 |

88 |

104 |

2840 |

94 |

75 |

60 |

9

X M8 |

41 |

1,950 |

| 65

x 84 |

55 |

72 |

80 |

88 |

111 |

3070 |

94 |

70 |

55 |

9 X M8 |

41 |

2,200 |

| 70

x 90 |

65 |

86 |

96 |

106 |

119 |

5250 |

150 |

90 |

70 |

9

X M10 |

83 |

3,050 |

| 75

x 95 |

65 |

86 |

96 |

106 |

126 |

5600 |

150 |

80 |

65 |

9

X M10 |

83 |

3,300 |

| 80

x 100 |

65 |

86 |

96 |

106 |

131 |

8020 |

200 |

100 |

80 |

12

X M10 |

83 |

3,500 |

| 85

x 106 |

65 |

86 |

96 |

106 |

137 |

8500 |

200 |

95 |

75 |

12

X M10 |

83 |

3,800 |

| 90

x 112 |

65 |

86 |

96 |

106 |

144 |

9000 |

200 |

90 |

75 |

12

X M10 |

83 |

4,200 |

| 95

x 120 |

65 |

86 |

96 |

106 |

149 |

11000 |

230 |

100 |

80 |

14

X M10 |

83 |

4,750 |

| 100

x 125 |

65 |

86 |

96 |

106 |

154 |

15000 |

300 |

120 |

95 |

12 X M12 |

83 |

4,880 |

| 110

x 140 |

90 |

114 |

128 |

140 |

180 |

16000 |

290 |

80 |

65 |

12

X M12 |

145 |

8,950 |

| 120

x 155 |

90 |

114 |

128 |

140 |

198 |

17500 |

290 |

70 |

55 |

12

X M12 |

145 |

11,500 |

| 131

x 165 |

90 |

114 |

128 |

140 |

208 |

25000 |

384 |

90 |

70 |

16

x M12 |

145 |

12,100 |