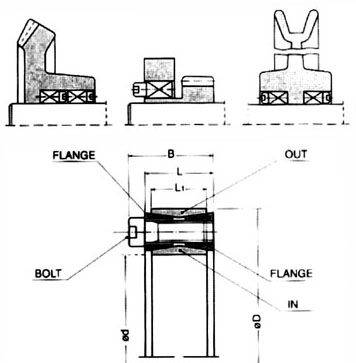

LOCKING ELEMENTS - SWLE 200 TYPE

|

|

Dimensions (mm)

| SWLE

200 d x D |

Dimensions

|

Transmissible |

Surface

Preassure |

Bolt |

Weight (g) |

||||||

| L |

L1 |

B |

Torque Mt(kgf-m) |

Axial

Load Pax(kgf) |

Shaft kgf/mm2 |

Boss kgf/mm2 |

Holes |

Thread Dia |

Torque (kgf-m) |

||

20

X 47 |

20 |

17 |

27.5 |

27 |

2760 |

27 |

11 |

8 |

M

6 |

1.4 |

208 |

| 22

X 47 |

20 |

17 |

27.5 |

30 |

2760 |

24.5 |

11.5 |

8 |

M

6 |

1.4 |

198 |

24

X 50 |

20 |

17 |

27.5 |

37 |

3110 |

25 |

12 |

8 |

M

6 |

1.4 |

216 |

| 25

X 50 |

20 |

17 |

27.5 |

39 |

3110 |

24 |

12 |

8 |

M

6 |

1.4 |

210 |

28

X 55 |

20 |

17 |

27.5 |

48 |

3450 |

24 |

12 |

10 |

M

6 |

1.4 |

256 |

| 30

X 55 |

20 |

17 |

27.5 |

52 |

3460 |

22.5 |

12.5 |

10 |

M

6 |

1.4 |

244 |

32

X 60 |

20 |

17 |

27.5 |

66 |

4150 |

25 |

13.5 |

12 |

M

6 |

1.4 |

294 |

| 35

X 60 |

20 |

17 |

27.5 |

72 |

4150 |

23 |

13.5 |

12 |

M

6 |

1.4 |

276 |

38

X 65 |

20 |

17 |

27.5 |

91 |

4840 |

25 |

14.5 |

14 |

M

6 |

1.4 |

320 |

| 40

X 65 |

20 |

17 |

27.5 |

96 |

4840 |

23.5 |

14.5 |

14 |

M

6 |

1.4 |

308 |

42

X 75 |

24 |

20 |

33.5 |

158 |

7520 |

30 |

17 |

12 |

M

8 |

3.4 |

556 |

| 45

X 75 |

24 |

20 |

33.5 |

170 |

7520 |

28 |

17 |

12 |

M

8 |

3.4 |

522 |

48

X 80 |

24 |

20 |

33.5 |

181 |

7520 |

26 |

15.5 |

12 |

M

8 |

3.4 |

578 |

| 50

X 80 |

24 |

20 |

33.5 |

190 |

7520 |

25 |

15.5 |

12 |

M

8 |

3.4 |

564 |

55

X 85 |

24 |

20 |

33.5 |

242 |

8800 |

26.5 |

17 |

14 |

M

8 |

3.4 |

610 |

| 60

X 90 |

24 |

20 |

33.5 |

264 |

8800 |

24.5 |

16 |

14 |

M

8 |

3.4 |

644 |

65

X 95 |

24 |

20 |

33.5 |

327 |

10000 |

26 |

17.5 |

16 |

M

8 |

3.4 |

690 |

| 70

X 110 |

28 |

24 |

39.5 |

480 |

13600 |

27 |

17 |

14 |

M

10 |

6.6 |

1,214 |

75

X 115 |

28 |

24 |

39.5 |

510 |

13600 |

25 |

16.5 |

14 |

M

10 |

6.6 |

1,280 |

| 80

X 120 |

28 |

24 |

39.5 |

540 |

13600 |

24 |

16 |

14 |

M

10 |

6.6 |

1,346 |

85

X 125 |

28 |

24 |

39.5 |

660 |

15600 |

25.5 |

17.5 |

16 |

M

10 |

6.6 |

1,424 |

| 90

X 130 |

28 |

24 |

39.5 |

700 |

15600 |

24 |

16.5 |

16 |

M

10 |

6.6 |

1,472 |

95

X 135 |

28 |

24 |

39.5 |

830 |

17600 |

25.5 |

18 |

18 |

M

10 |

6.6 |

1,546 |

| 100

X 145 |

33 |

26 |

47 |

990 |

19800 |

25.5 |

17.5 |

14 |

M

12 |

11.5 |

2,132 |

110

X 155 |

33 |

26 |

47 |

1090 |

19800 |

23 |

16.5 |

14 |

M

12 |

11.5 |

2,306 |

| 120

X 165 |

33 |

26 |

47 |

1360 |

22700 |

24 |

17.5 |

16 |

M

12 |

11.5 |

2,400 |

130

X 180 |

38 |

34 |

52 |

1840 |

28400 |

21.5 |

15.5 |

20 |

M

12 |

11.5 |

3,500 |

| 140

X 190 |

38 |

34 |

52 |

2180 |

31200 |

22 |

16 |

22 |

M

12 |

11.5 |

3,848 |

150

X 200 |

38 |

34 |

52 |

2550 |

34000 |

22 |

16.5 |

24 |

M

12 |

11.5 |

4,100 |

| 160

X 210 |

38 |

34 |

52 |

2950 |

36900 |

22.5 |

17 |

26 |

M

12 |

11.5 |

4,400 |

170

X 225 |

44 |

38 |

60 |

3560 |

41900 |

21.5 |

16.5 |

22 |

M

14 |

18.0 |

5,800 |

| 180

X 235 |

44 |

38 |

60 |

4110 |

45700 |

22 |

17 |

24 |

M

14 |

18.0 |

6,100 |

190

X 250 |

52 |

46 |

68 |

5060 |

53300 |

20 |

15.5 |

28 |

M

14 |

18.0 |

8,300 |

| 200

X 260 |

52 |

46 |

68 |

5710 |

57100 |

20.5 |

16 |

30 |

M

14 |

18.0 |

8,700 |

220

X 285 |

56 |

50 |

74 |

7410 |

67400 |

20.5 |

15.5 |

26 |

M

16 |

28.0 |

11,300 |

| 240

X 305 |

56 |

50 |

74 |

9330 |

77800 |

21.5 |

17 |

30 |

M

16 |

28.0 |

12,200 |