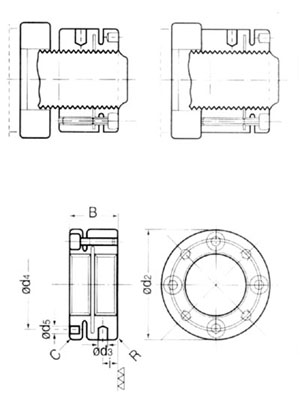

PRECISION LOCK NUT - YAN TYPE

| Features |

|

|

| - Material | : DIN C45, JIS S45C | |

| : KS SM45C | ||

| - Hardness | : HRC 22 ~ 25 | |

| - Nut Grade | ||

| - Squarness of Nut Face | : ±0.003 | |

|

||

|

||

DIMENSIONS (mm)

|

PART

NO. |

DIMENSIONS |

Holes

|

Tight

bolt |

Release

torque (kgf.m) |

Allowable

Axial Load (kgf-m) |

Weight (g) |

|||||||

|

d2 |

d3 |

d4 |

d5 |

B |

i |

Thread

& Length |

Bolts |

Torque (kgf.m) |

|||||

| YAN

16X1.5 |

34 |

4 |

24.5 |

4.3 |

18 |

5 |

4 |

M4

X 12 |

4 |

0.29 |

340 |

22 |

80 |

|

YAN

18 X 1.5 |

36 |

4 |

26.5 |

4.3 |

18 |

5 |

4 |

M4

X 12 |

4 |

0.29 |

370 |

24 |

87 |

|

YAN

20 X 1.5 |

40 |

4 |

30.5 |

4.3 |

18 |

5 |

4 |

M4

X 12 |

4 |

0.29 |

400 |

27 |

107 |

|

YAN

22 X 1.5 |

40 |

4 |

30.5 |

4.3 |

18 |

5 |

4 |

M4

X 12 |

4 |

0.29 |

420 |

30 |

100 |

YAN

24 X 1.5 |

42 |

4 |

32.5 |

4.3 |

18 |

5 |

4 |

M4

X 12 |

4 |

0.29 |

440 |

33 |

107 |

|

YAN

25 X 1.5 |

45 |

5 |

36.5 |

4.3 |

20 |

6.5 |

4 |

M4

X 12 |

4 |

0.29 |

450 |

45 |

137 |

YAN

28 X 1.5 |

46 |

5 |

38.5 |

4.3 |

20 |

6.5 |

4 |

M4

X 12 |

4 |

0.29 |

480 |

50 |

136 |

|

YAN

30 X 1.5 |

48 |

5 |

40.5 |

4.3 |

20 |

6.5 |

4 |

M4

X 12 |

4 |

0.29 |

500 |

55 |

141 |

YAN

32 X 1.5 |

50 |

5 |

42.5 |

4.3 |

22 |

7 |

4 |

M4

X 12 |

4 |

0.29 |

520 |

61 |

163 |

|

YAN

35 X 1.5 |

53 |

5 |

45.5 |

4.3 |

22 |

7 |

4 |

M4

X 16 |

4 |

0.29 |

550 |

62 |

175 |

YAN

38 X 1.5 |

58 |

5 |

48.5 |

4.3 |

22 |

7 |

4 |

M4

X 16 |

4 |

0.29 |

580 |

72 |

212 |

|

YAN

40 X 1.5 |

58 |

5 |

50.5 |

4.3 |

22 |

7 |

4 |

M4

X 16 |

4 |

0.29 |

600 |

63 |

195 |

YAN

42 X 1.5 |

60 |

5 |

52.5 |

4.3 |

22 |

7 |

4 |

M4

X 16 |

4 |

0.29 |

620 |

63 |

204 |

|

YAN

45 X 1.5 |

68 |

6 |

58 |

4.3 |

22 |

6.5 |

6 |

M4

X 16 |

4 |

0.29 |

1,070 |

80 |

288 |

YAN

48 X 1.5 |

68 |

6 |

59.5 |

4.3 |

25 |

9 |

6 |

M4

X 16 |

6 |

0.29 |

1,180 |

90 |

294 |

|

YAN

50 X 1.5 |

70 |

6 |

61.5 |

4.3 |

25 |

9 |

6 |

M4

X 18 |

6 |

0.29 |

1,250 |

90 |

303 |

YAN

52 X 1.5 |

72 |

6 |

63.5 |

4.3 |

25 |

9 |

6 |

M4

X 18 |

6 |

0.29 |

1,300 |

90 |

314 |

|

YAN

55 X 1.5 |

75 |

6 |

66.5 |

4.3 |

25 |

9 |

6 |

M4

X 18 |

6 |

0.29 |

1,410 |

90 |

327 |

YAN

58 X 1.5 |

82 |

6 |

72.5 |

5.3 |

26 |

9 |

6 |

M4

X 18 |

6 |

0.29 |

2,100 |

158 |

446 |

|

YAN

60 X 1.5 |

84 |

6 |

74.5 |

5.3 |

26 |

9 |

6 |

M5

X 18 |

6 |

0.6 |

2,200 |

158 |

479 |

YAN

62 X 1.5 |

86 |

6 |

76.5 |

5.3 |

28 |

10.5 |

6 |

M5

X 18 |

6 |

0.6 |

2,310 |

180 |

505 |

|

YAN

65 X 1.5 |

88 |

6 |

78.5 |

5.3 |

28 |

10.5 |

6 |

M5

X 20 |

6 |

0.6 |

2,470 |

170 |

500 |

YAN

68 X 1.5 |

95 |

8 |

83 |

5.3 |

28 |

9.5 |

6 |

M5

X 20 |

6 |

0.6 |

2,620 |

215 |

625 |

|

YAN

70 X 1.5 |

95 |

8 |

85 |

5.3 |

28 |

9.5 |

6 |

M5

X 20 |

6 |

0.6 |

2,730 |

200 |

536 |

|

YAN

72 X 1.5 |

98 |

8 |

86 |

6.4 |

28 |

8.5 |

6 |

M5

X 20 |

6 |

1.0 |

3,640 |

158 |

626 |

|

YAN

75 X 1.5 |

100 |

8 |

88 |

6.4 |

28 |

8.5 |

6 |

M6

X 20 |

6 |

1.0 |

3,750 |

200 |

623 |

|

YAN

80 X 2.0 |

110 |

8 |

95 |

6.4 |

32 |

11 |

6 |

M6

X 20 |

6 |

1.0 |

3,900 |

169 |

890 |

|

YAN

85 X 2.0 |

115 |

8 |

100 |

6.4 |

32 |

11 |

6 |

M6

X 22 |

6 |

1.0 |

4,000 |

167 |

963 |

|

YAN

90 X 2.0 |

120 |

8 |

108 |

6.4 |

32 |

11 |

6 |

M6

X 22 |

6 |

1.0 |

4,200 |

255 |

1,020 |

|

YAN

95 X 2.0 |

125 |

8 |

113 |

6.4 |

32 |

11 |

6 |

M6

X 22 |

6 |

1.0 |

4,350 |

262 |

1,050 |

|

YAN

100 X 2.0 |

130 |

8 |

118 |

6.4 |

32 |

11 |

6 |

M6

X 22 |

6 |

1.0 |

4,500 |

268 |

1,100 |

|

YAN

105 X 2.5 |

135 |

8 |

123 |

6.4 |

32 |

11 |

6 |

M6

X 22 |

6 |

1.0 |

4,650 |

270 |

1,150 |

|

YAN

110 X 2.0 |

140 |

8 |

128 |

6.4 |

32 |

11 |

6 |

M6

X 22 |

6 |

1.0 |

4,800 |

280 |

1,210 |

|

YAN

115 X 2.0 |

145 |

8 |

133 |

6.4 |

36 |

13 |

6 |

M6

X 22 |

6 |

1.0 |

4,950 |

325 |

1,430 |

|

YAN

120 X 2.0 |

155 |

8 |

140 |

6.4 |

36 |

13 |

6 |

M6

X 25 |

6 |

1.0 |

5,100 |

403 |

1,740 |

|

YAN

125 X 2.0 |

160 |

8 |

148 |

6.4 |

36 |

13 |

6 |

M6

X 25 |

6 |

1.0 |

5,250 |

410 |

1,820 |

|

YAN

130 X 3.0 |

165 |

8 |

153 |

6.4 |

36 |

13 |

6 |

M6

X 25 |

6 |

1.0 |

5,450 |

400 |

1,940 |

YAN

140 X 3.0 |

180 |

10 |

165 |

6.4 |

36 |

12 |

8 |

M6

X 25 |

8 |

1.0 |

5,700 |

472 |

2,335 |

YAN

150 X 3.0 |

190 |

10 |

175 |

6.4 |

36 |

12 |

8 |

M6

X 25 |

8 |

1.0 |

6,000 |

485 |

2,480 |

YAN

160 X 3.0 |

205 |

10 |

185 |

8.4 |

40 |

14 |

8 |

M6

X 25 |

8 |

2.5 |

6,300 |

550 |

3,380 |

YAN

170 X 3.0 |

215 |

10 |

195 |

8.4 |

40 |

14 |

8 |

M8

X 30 |

8 |

2.5 |

6,650 |

555 |

3,580 |

YAN

180 X 3.0 |

230 |

10 |

210 |

8.4 |

40 |

14 |

8 |

M8

X 30 |

8 |

2.5 |

7,000 |

640 |

4,110 |

YAN

190 X 3.0 |

240 |

10 |

224 |

8.4 |

40 |

14 |

8 |

M8

X 30 |

8 |

2.5 |

7,300 |

650 |

4,330 |

YAN

200X 3.0 |

245 |

10 |

229 |

8.4 |

40 |

14 |

8 |

M8

X 30 |

8 |

2.5 |

7,600 |

570 |

4,410 |