|

|

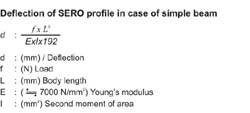

sero

(which is belt driven type) is a light & hish speed module made

up with aluminium body combined with steel guide shaft and special

machined speed guide carrier as it's slider. Belt tension cab be

adjusted easily by lightening screw simply and it is easy to expand

to several axis usage. |

* |

Maximum

speed : 8 m/s Maximum length : 4 M without any jointing (6M available on special order) Assembling Module : Using slot on the slide of aluminium body Repeatability: ±0.05mm |

* * * |

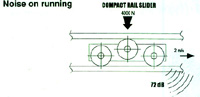

Running

accuracy : 0.08 mm/m Assembling slider : Using slot of block cover Belt : HTD5 or S5M built-in Core. No blacklash no turning point. |

SERO

(the most up-to-datelinear module integrated on Speed Guide) is

easy to adjust clearance and guarantee smooth running with high

speed. Adding to this, it has excellent load capacity and light

running accuracy compared with the same level. Also, has dust-proof

feature. |

* |

Order

Example SERO61000-SM-3-SERO61 - stroke 1000mm - belt type S5M- order q'ty,, 3pcs P-SERO81 - UP - 2 - Part of SERO81 -Upper cover of pulley box-2 pcs. P-SERO61 - SL - 3 - Part of SERO61 - Slider - 3 pcs. |

| Load & Moment of SERO | Lifespan Calculation |

|

||

|

C

: (N)/Effective dynamic load |

F1

: (N)/Effective dynamic load

|

|

|

Efective dynamic load

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Service factor |

Stroke factor |

||||||||||||||||||||||||||||

|

|

|

Calculating motor torque

|

|||||||||||||||||||||||||||||

|

|